Precision press processing technology realizing high cost effectiveness.

This is a critical component for realizing reliable shifting operation of manual transmission. In addition to the shape complexity, strict dimensional accuracy are required.

Unlike conventional interlocking sleeve, which was a sintered part, the new interlocking sleeve is made by ring mash welding the precision press part and pipe together to realize an optimal balance between low cost and high functionality. It requires advanced technological ability to perform ring mash welding while minimizing subtle displacement for satisfying stringent accuracy requirements.

* The method has been patented at the ring mash weld process.

The manual plate determines the shift position in automatic transmission. All results of shift lever operations are transmitted to various other parts through this component. Therefore, strict dimensional accuracy and high strength are required. Conventionally, this component was manufactured by machining process.

For smooth shift operations, smooth shear plane is formed by fine press processing for entire tooth face of the manual plate. Combining ring mash welding and fine press enables significant reduction of cost while satisfying strict requirements.

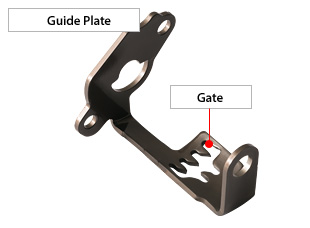

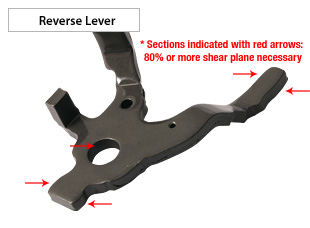

Guide plate is a component for switching the transmission gears in manual transmission (MT). Reverse lever is a component for switching to the reverse gear in manual transmission (MT). These components affect the shift operation feel when switching the transmission gears. Therefore, strict surface position accuracy and a wide shear plane range are required.

Because high accuracy is required for surface position and coaxiality, sintering and machining had been used for conventional products. However, for cost reduction, now we use high precision press processing for sheet metal and perform machining only for portions where accuracy deviation occurs due to quench distortion.

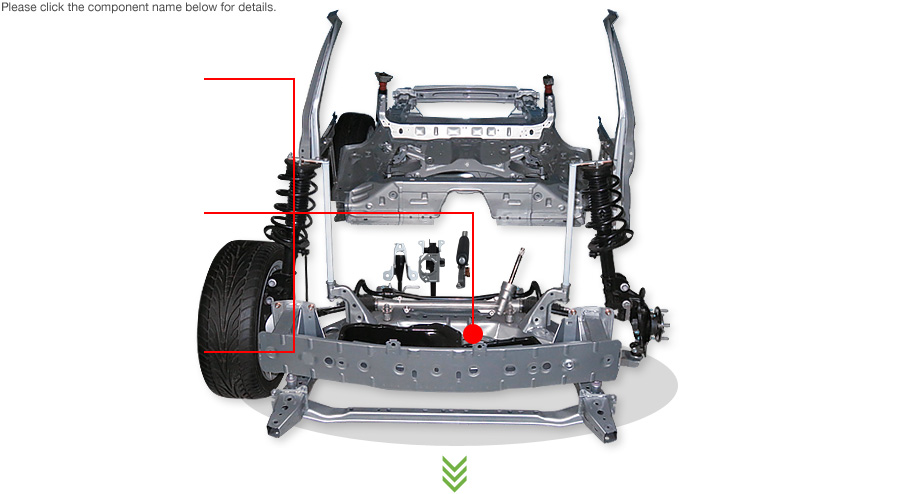

Oil pan, located under the engine and transmission, receives lubricating oil to prevent leakage to the outside. Vibration-proof property is required for this component.

To suppress vibration generated from the diesel engine, vibration-proof sheet metal material is used, which has resin between sheets. In addition, deep drawing products, which takes into consideration the movement of oil to left or right by centrifugal force when making turns, are manufactured.

Copyright(C) Y-TEC CORPORATION All Rights Reserved.