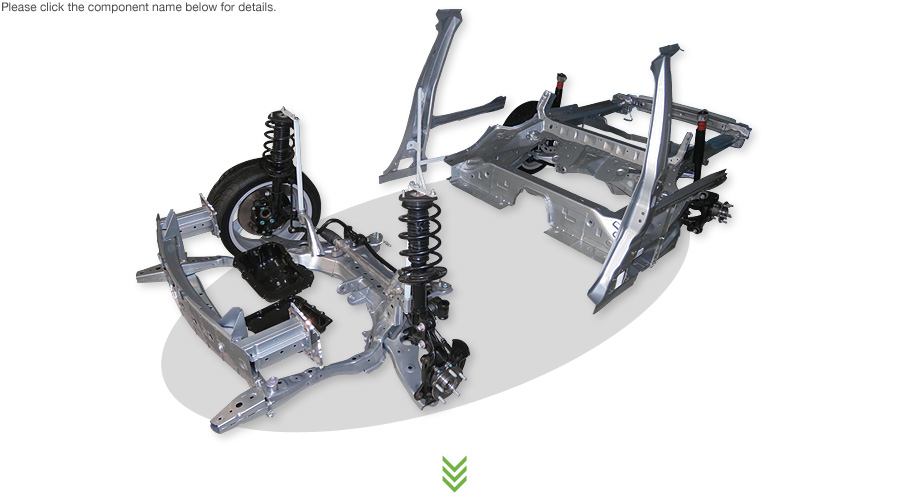

Coordination of light weight and safety at a high level.

With this component, bending and torsion while driving are suppressed to improve driving performance. Also, in the event of a collision, it protects the occupants and fuel tank from the collision impact.

Taking advantage of our technologies of ultra-high tensile steel (1180MPa) processing and different iron material welding, our capability to manage variety of materials leads to weight saving, which contributes to fuel consumption improvement.

Ultra hight-tensile materials of 980MPa and 780MPa grades are welded together to produce sufficient strength while achieving weight reduction.

Required strength and weight saving of our products are gained by combined application of ultra-high tensile materials such as 980MPa and 1180MPa steels.

This collision-resistant component is built inside the doors. The main role of this component is to absorb the impact in the event of a lateral collision to lessen damages to the occupants.

Increased strength (up to 1500MPa grade) enabled the use of thinner materials, thereby leading to weight reduction.

Bumper reinforcement is fixed to the front and rear of the vehicle to increase resistance to collision impacts. It absorbs the impact in the event of a collision to lessen damages to the occupants.

Strength of 1800MPa grade allowed significant weight reduction compared to conventional components.

B-Pillar is a body structure part positioned between the vehicle front door and the rear door. It requires the strength enough to secure the survival space for passengers in case of the vehicle collision or over-turning as well as the performance of enhanced body structure stiffness.

Patchwork hot stamping, in which the reinforcement component is spot-welded to the mother part before heating, can efficiently form complex shapes with multiple material thicknesses with the high broadside crash performance satisfied and with the product weight saved.

Copyright(C) Y-TEC CORPORATION All Rights Reserved.