For the purpose of weight reduction, materials used in automobiles are becoming increasingly thinner in automotive industry nowadays. To enable ourselves to take on the difficulties of arc welding of thin sheet metals, we conduct continuous research and development, and bring the technological advancements born from which to the production lines. We ceaselessly seek for cutting-edge welding technologies to produce high-quality products.

Slags in weld beads in chassis parts often cause rust-looking objects and the real rust. We have developed high-argon welding to minimize the slags.

Conventionally operators visually checked the weld appearance after the robotic welding process. We have adopted auto checking machine for weld appearance to judge OK/NG numerically with 3D-scanned data, which enables unmanned process of the auto checking.

Flexible line is the production system in which different parts are produced with a single line. Integrating multiple lines into one single line can save investment and area. It can change over the jigs in short time without the production efficiency dropped. With jigs compatible, it can respond to the production volume fluctuation. Sequential production system meeting our customer's order of the production is adopted for inventory reduction.

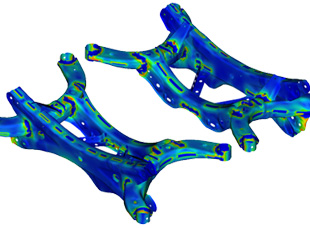

Thermal distortion by welding is one of the biggest issues for the chassis components, for which arc welding is frequently performed. We predict the amount of thermal distortion by simulation, and reflect the analysis results to the jig structure and component dimensions. By doing so, we are able to shorten the mass-production preparation time and variable-item production. To further reduce the preparation time, we are currently putting efforts into enhancing the database for improving the accuracy of analyses.

Copyright(C) Y-TEC CORPORATION All Rights Reserved.